新品 DALMO Y、YX3,YKS,YKK,YR,YRKS series medium-high voltage 3-phase asynchronous electric motor Y、YX3,YKS,YKK,YR,YRKS355~710/400~710/800-1000

#电机 #机床附件 #机床设备 #附件 #机床功能部件- 分类电机型号Y、YKS,YKK,YR,YRKS355~710品牌DALMO品牌范围国产品牌产地范围国产适用行业metallurgy, hoist, crane, petrochemistry,extinguish,ventilation system,metro,tunnel

- 详情

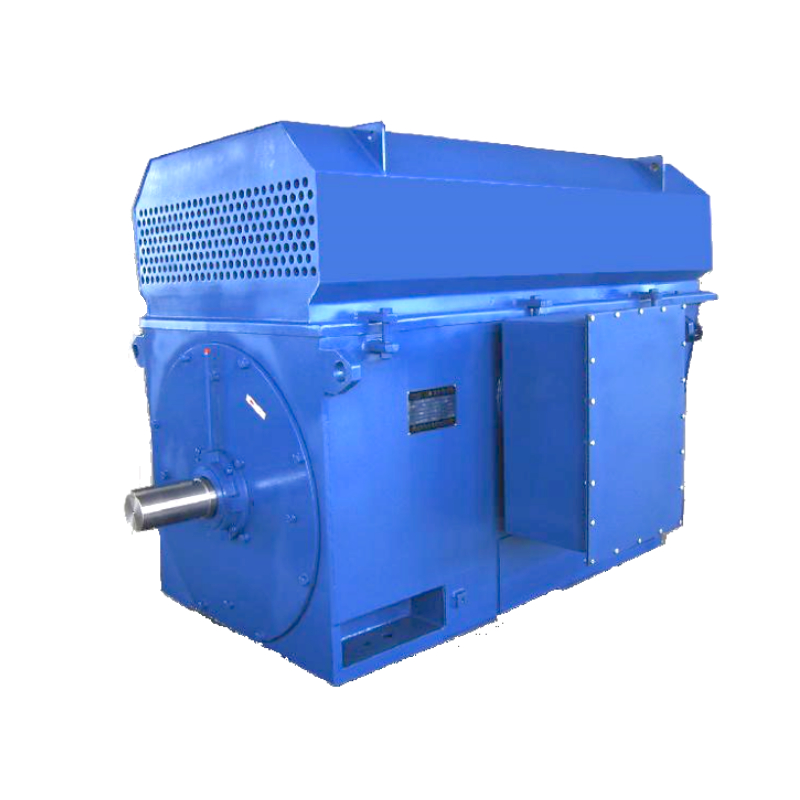

Y,YKS, YKK, YR, YRKS series meduim-high voltage three-phase asynchronous motors are optimized products designed and manufactured by our company using advanced technology at home and abroad and combining our company's practical experience in producing high voltage motors. It has the advantages of compact structure, light weight, high efficiency, energy saving, low noise, low vibration, high reliability, long service life, convenient installation and maintenance, etc.

This series of motors are suitable for driving all kinds of ventilators, compressors, water pumps, crushers, cutting machine tools, transportation machinery and other general machinery and other mechanical equipment, used as prime movers in mining, machinery, petroleum, chemical industry, power stations and other industrial and mining enterprises. If the motor used for driving blower, coal mill, rolling mill, rolling field machine, belt machine should provide the relevant technical information when ordering, and to sign the technical agreement, as the basis of the special design of the motor, to ensure the reliable operation of the motor.

Rated frequency 50Hz, rated voltage 3Kv, 6Kv and 10Kv, 60Hz and other voltage motors can also be manufactured according to order. The basic installation structure of this series of motors is horizontal with foot (IMB3) structure. The motor adopts box structure, the base is welded into box form by steel plate, light weight, good stiffness. There are Windows on both sides and at the top of the machine base, on the one hand, it is convenient for motor maintenance. On the other hand, different coolers are installed at the top, which can derive motors with different cooling modes and different protection levels. The stator winding of the stator structure, installation outside using with F class insulation materials, 10 kv motor adopts reliable corona proof measures, winding end have reliable fixed and banding, and USES the vacuum pressure impregnation process (VPI) without solvent paint processing, thus the insulation of the motor performance is good, high mechanical strength, moisture proof ability, long service life. The dragon rotor has two kinds of structure: cast aluminum and copper strip. It adopts advanced and reliable casting aluminum technology and welding technology, and passes dynamic balance check. Therefore, the motor runs smoothly and reliably. Bearing adopts rolling bearing and sliding bearing in two forms, depending on the motor power and speed, its protection grade is IP44 or IP54, rolling bearing is equipped with non-stop oil injection and discharge device. The main junction box is located on the right side of the motor (as seen from the shaft extension), or on the left side according to user needs. Separate terminals are provided inside and outside the junction box.

According to the needs of users, temperature measuring devices can be installed in important parts such as stator windings and bearings, so as to facilitate on-site observation and remote monitoring, so as to ensure safe and reliable operation of the motor. Y and YR series are basic series of motors, while YKS, YKK and YRKS series are derived from different cooling modes and protection grades of motors.

Instructions for Ordering:

● The motor model, pole number, rated power, rotation direction (from the end of the shaft) should be indicated when ordering. If the rotation direction is not indicated, supply clockwise.

● Y, YR series motors are equipped with stator temperature measuring elements.

● When the motor needs to install heater, please ask when ordering.

● If supporting machine is ventilator or coal mill, please inform the moment of inertia (J) or moment of inertia GD2 of the machine before ordering. If necessary, a separate technical agreement shall be concluded.

● The weight of the motor is estimated, and the error is ±10%.

● The technical parameters in the sample may change without prior notice as the product technology progresses and the relevant standards are updated and revised at home and abroad.

- 海报分享